When and why should pulse welding be performed?

Dec. 16, 2021

Dec. 16, 2021

Pulse welding is a form of welding in which the amperage alternates between high and low points. It keeps the overall heat input to the weld low, while still achieving the proper depth of melt.

Its pulse frequency, what the peak amperage is, what the base amperage is, and how long it spends at either amperage setting can all be adjusted to fit the weld you are making.

Pulse Percentage (%)

The pulse percentage is the amount of time each pulse spends in peak and base amperage. If you set the percentage to 50%, this means that 50% of the pulse period will be peak amperage and 50% of the pulse will be base amperage.

You can adjust this either way, where 90% is almost entirely peak amps and 20% is almost no peak amps. The more time you spend on the peak amp portion of the pulse, the more penetration you will get, and vice versa.

Pulse Frequency/Pulse Hertz

Pulse frequency or pulse hertz is the same thing: the number of pulses per second. For example, UNIMIG AC/DC machines have a pulse frequency range of 0.5-200Hz per second. this means that 1Hz equals one pulse per second, while 50Hz equals 50 pulses per second.

One pulse per second is relatively slow and easy for your eyes to track. 30 or more pulses are quite fast and it is difficult to see individual pulses. anything between the 5-30 pulse range can be painful for your eyes. It's kind of like staring at a flash light, it's very uncomfortable to watch and it's hard to concentrate on the weld timing.

When it comes to choosing how many pulses per second you want, it really depends on the application. If you are welding thin material, then fast pulses are usually better and will leave a high profile weld. If you are welding thicker materials, then a slow pulse is usually better and will leave a low profile weld.

TIG Pulse Welding

Pulse welding with TIG is done in almost the same way as standard TIG welding. There are only a few additional settings that need to be adjusted on the machine first. However, when you pulse weld with TIG, you can feed the filler bar in two ways (instead of one).

1. The first method is your standard tap. Depending on how many pulses per second you have it set to, you can tap the peak and pause the basic amplifier. If you only have one pulse per second, this is not hard to adapt. However, if you weld at about 50 pulses per second, your tap times can remain consistent because there is virtually no way to time the pulses because your eyes can barely see them anymore.

2. The second method is to place the wire in the joint. Now, instead of just laying it flat and soldering to it, you place the tip of the rod on the leading edge of the puddle and drag it down the weld, keeping it incorporated in the leading edge.

Both techniques work and you can use either method regardless of your number of pulses per second, but if you use the layout method on a high pulse, you won't see stacked dimes. It's still a good penetrating weld, but it won't be as aesthetically pleasing.

When you pulse, you can still use the foot pedal. You can keep it at full throttle and keep your peak amp at the level you set it at, or you can pulse within the pulse.

This means that if you have been pulsing but you still think the weld is getting too hot, you can release the pedal and lower the peak amplifier in the pulse. Your background (base) amplifier will remain the same, but the higher part of the cycle will be slightly cooler.

For example, suppose you have set the machine's peak amperage to 200 and set the base amperage to 50. depressing the foot pedal will keep the peak amperage at 200 for the entire weld.

However, if you loosen the foot pedal, your peak amp will go down to, say, 150 and your base amp will stay at 50. So, overall, the entire weld will be cooler because your peak amp is not as hot.

Then, if you decide you need more heat again, you can go back to fully depressing the pedal and increase back to the original 200 amps.

MIG Pulsed

There are two types of pulsed MIG welding.

1. Single Pulse - Single Pulse MIG is a spray transfer that, like TIG, alternates between peak and background currents.

MIG pulses usually do not spatter because the wire never actually touches the weld. At the peak of the cycle, droplets of metal are "sprayed" into the weld.

The background current of the pulse cycle is not enough to transfer the metal. It just holds the arc. It produces all the benefits of spray transfer (speed, no spatter, deep penetration) without all the excess heat.

Single pulse MIG welding has a sound similar to AC TIG welding with a constant high pitched beep.

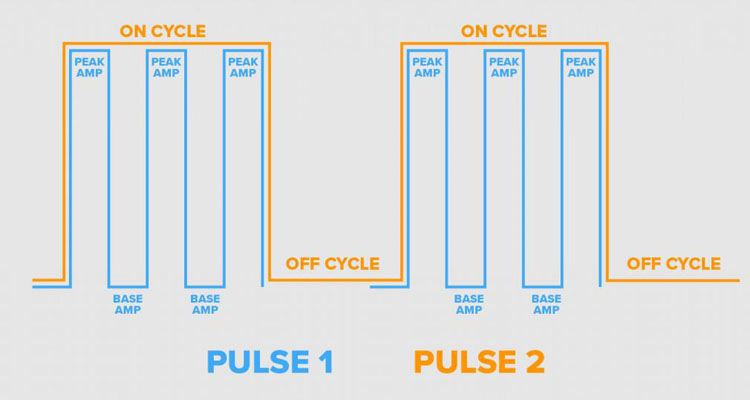

2. Double Pulse - A double pulse is two pulses that occur simultaneously.

The first pulse is a standard (see: single) pulse with a peak amplifier and a base amplifier.

The second pulse, which does not transmit any wire, turns the first pulse on and off during its cycle. During the second pulse, the arc is still present, but the temperature is so low that no welding occurs.

When the second pulse is "on", the first pulse takes over (turns on) and alternates between peak amperage and base amperage, creating a weld in the same way as a single pulse. When the second pulse is "off," nothing happens.

Double pulse MIG welding is a cooling procedure because there is more downtime between high current moments, so you need to use more current in the peak to get full penetration.

It is ideal for aesthetically pleasing welds because it allows you to create the stacking angle effect of TIG using a MIG machine without the effort of an operator. It is accompanied by an intermittent high pitched buzzing sound.

These processes can be synergistic, in which the welder makes your life very easy and chooses all the best settings for you. Or, it can be non-synergistic, where you have to enter each value yourself (which, frankly, requires some serious iterations, especially when double pulses are involved).

Although the arc itself does not look pulsating, it sounds different from normal MIG welding, whether it is single or double pulsing.

As puzzling and confusing as it sounds, the actual weld when pulsing with a MIG is just like a standard MIG weld. After setting up the machine, you simply press the trigger on the torch and weld along the joint. It does the rest of the work for you.

Why should we use pulse welding?

Pulse welding focuses the arc and makes the weld path smaller, so it stays in place. It's not only easier to control, but you still have full penetration.

The puddle freezes as you enter the basic amp portion of the pulse cycle, and the cooling at that moment helps the weld to level out. The longer you spend on the background amplifier, the better the "puddle freeze" effect, which is what creates the appearance of a stacked dime.

Pulse welding also completely eliminates spatter, so you don't have to do any post-weld cleanup.

When should we pulse weld?

❉ Stainless steel, aluminum and other highly thermally conductive metals

Pulse not only helps prevent sheet metal distortion, but is often used with known heat sink metals. Cooler welds provide all the penetration needed without exploding the metal with excessive heat.

❉ Misalignment Welding

The cooling of the puddle makes it smaller meaning it is less likely to drip. If you weld misaligned, the use of pulses will keep the weld where it should be, not on you.

❉ Sheet Metal

Pulse welding is cooler than standard welding due to the low current intensity. The less heat there is in the metal, the less distortion there is, which is perfect for thin materials.

❉ Hole Filling

The ability to weld without applying too much heat to the metal makes filling holes much easier. At lower heat levels, there is much less chance of blowing farther through the hole (or usually through the metal).

❉ Different metal thicknesses

Just like welding mismatches, pulses help hold the weld pool exactly where you want it, which makes it easier to weld thin parts to thick parts. This is especially true when welding lap joints consisting of two different sizes. You don't have to worry about the pool spilling over the top edge.

❉ No Spatter

By all means, this isn't really an issue when you're TIG welding, but when you're MIG welding, less spatter means less cleanup after the weld is done.

Pulse welding isn't the only method that works for any of these applications, but it does make some of the more difficult welds much easier.